Montour Railroad

Montour Railroad

|

|

Coverdale Mine No. 8 Pittsburgh Terminal Coal

Corporation Mine No. 8 Bob Ciminel - Roswell, Georgia Read Bob Ciminel's full report on the Coverdale Mine. The Coverdale Mine was located along the Montour Railroad between Library Junction and Brightwood. The mine's surface facilities stretched along what is now Industrial Boulevard in Bethel Park, a suburb of Pittsburgh. The

mine was serviced by the Pittsburgh & West Virginia Railway, and

before that the West Side Belt Railroad, using trackage rights between

Salida and a point 2,000 feet west of the west switch at Coverdale

Siding. P&WV trains ran on Montour train orders issued by the

Montour dispatcher. The mine began operation in the Twenties and operated until 1947. It appears that the hoisting shafts and tipple were completed in 1922. Coverdale had one of the largest "patches," called Coverdale Village, in southwestern Pennsylvania. There were over 250 individual land lots, in addition to a large bunkhouse.

Geologically, the mine was located on the McMurray Syncline, or underground valley, where the normally easy-to-reach Pittsburgh Coal Seam was 340 feet beneath the surface. Mines located on either side of the syncline could reach the coal through simple drift entries dug into the nearest hillside. The Montour No. 10 Mine, located south of Coverdale in Library, reached the Pittsburgh Seam through drifts driven into the valley walls of Piney Fork. On the plus side, mines that operated at the bottom of the syncline usually found a thicker coal seam. The seam at Coverdale could have been eight feet thick. In 1922, the Coverdale Mine complex was considered state-of-the-art because of the modern electrical system, hoisting equipment, and coal processing system installed. The mine received alternating current (AC) electrical power at 22,000 volts from the transmission lines and reduced it to 2,300 volts using transformers. The power then went to the main switchboard where it was either converted to direct current (DC) for use underground, or distributed to the various surface facilities, such as the main hoist, auxiliary hoist, mine fan, and tipple. To produce DC power, the mine had two motor-generator sets that used a 2300-volt AC, 433-horsepower motor to drive a 275-volt DC, 300-kilowatt generator. Underground power went down the shaft in two cable encased in metal conduit where one circuit fed the overhead trolley wire and the other supplied power to the coal cutting machines. In 1922, the mine was still using mules to haul the coal from the working face to the shaft, but the electrical system was designed for the eventual installation of rail haulage using electric locomotives.

Coverdale used an auxiliary hoist installed over the main air intake shaft driven by a 250-hp motor. Safety features include a speed limiting system, a switch to prevent over-winding the hoist and a recording system to show how the hoist was being operated. The

fan house was a brick building that contained the 200-hp, variable

speed fan motor that drove the huge exhaust fan. As the mine grew and

expanded, plans were already in place to upgrade the fan to a 300-hp

motor. A small diesel engine could also be connected to the fan to

operate it during power failures. Continuous ventilation to sweep

methane gas out of the mine was one of the most important facets of

mine safety. The main shaft was rectangular with semi-circle ends and lined with concrete from the landing blocks to the shaft collar. It was topped by a 65-foot steel head-frame over the two hoisting compartments, which each contained a self-dumping cage capable of holding two 5,000-lb capacity mine cars side by side. The Coverdale tipple was constructed of steel and concrete. The two pit cars that come up on the main hoist automatically dumped onto a scale at the top of the tipple. From the weigh pans, the coal either went to a screening table or was diverted to the run-of-mine loadout. The use of circular picking tables was unique to the Coverdale Mine, but they saved a lot of space compared to the rectangular tables used at most mines. Slate and rock were sent to a storage bin through air-operated gates and then taken out to the mine dump on an electrically-driven larry car. Bob Ciminel

©2009 |

|||||||||||||||

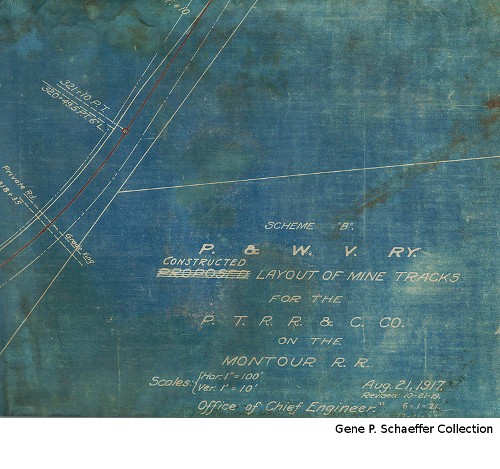

This is a slightly worn, blue print of the mine track layout at Coverdale of Pittsburgh Terminal Mine #8 that was a exclusinve P&WV operation via trackage rights over the Montour RR from Salida to a point near present days Brookside Lumber. I uncovered ths layout print during a later visit to Rook long after W.N.P. and myself preserved the records stored inside. The General Office Bldg at Rook was, and still is in shambles. Windows missing, water everywhere from a leaky roof. During those first visits in the early 1990's, we could only access the GOB when a W&LE Real Estate employee was present, and only for a few hours during each visit. When you have so much material, its easy to forget what all is in the archives. If this blue print was so darn big, I'd scan it. Whats really so neat, is the main track of the Montour RR is clearly defined - Gene P. Schaeffer |

||||||||||||||||